Independent Metallurgical Operations and Metallurgy are proud to have significantly contributed to the Pre-Feasibility Study (PFS) for Sarytogan Graphite’s project in Central Kazakhstan.

Together, our teams collaborated closely with Sarytogan MD Sean Gregory and his team on:

– Comminution test work;

– Beneficiation flowsheet development primarily through flotation;

– Bulk beneficiation concentrate generation;

– Metallurgy representation and ASX competent person signoff; and

– Collation of the overarching PFS Metallurgy section (included both beneficiation and refinery testwork conducted by various local and international laboratories) and competent person signoff.

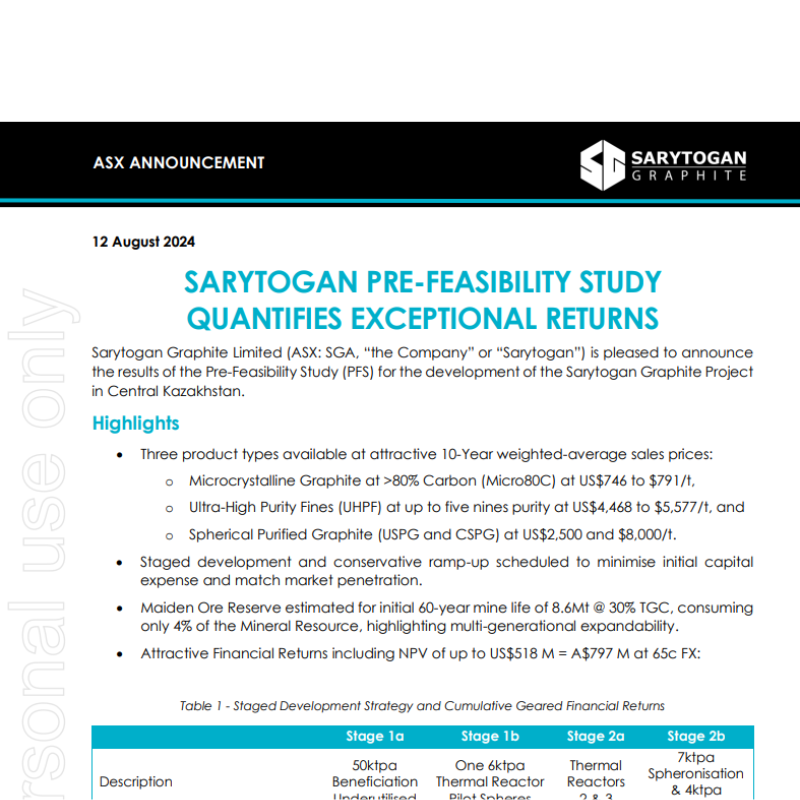

We extend our congratulations to Sarytogan Graphite on successfully producing three key product types:

– Microcrystalline Graphite: Used in traditional industries such as refractories, crucibles, foundries, friction parts, pencils and lubricants;

– Uncoated Spherical Purified Graphite for use in lithium ion batteries; and

– Ultra-High Purity Fines: Achieving up to five nines purity total graphitic carbon suitable for use in high income nuclear applications plus alkaline and lithium primary battery cathode conductivity enhancer.

The critical role of graphite in battery manufacturing and its applications in solar and wind energy underscore its importance to the clean energy sector.